The Miracles of Microprocessors

11 fascinating CPU facts

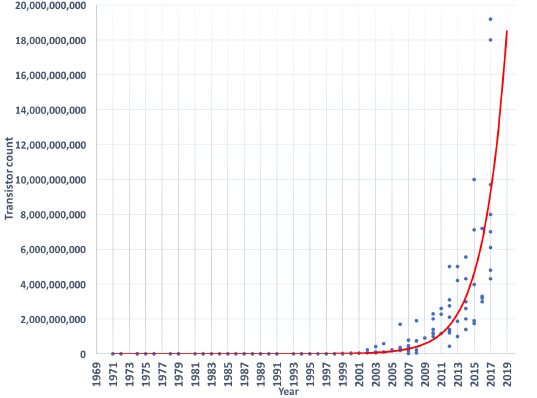

1. The transistors in modern microprocessors are so small that they are measured in nanometers (nm). The Apple M1 chip, for example, uses a 5nm manufacturing process, meaning that the transistors (small switches) on the chip are just 5 billionths of a meter wide. To put this into perspective, an average human hair is roughly 100,000 nm wide, about 20,000 times wider than the smallest transistors.

In 2024, consumer grade CPU's can contain over 100 billion transistors.

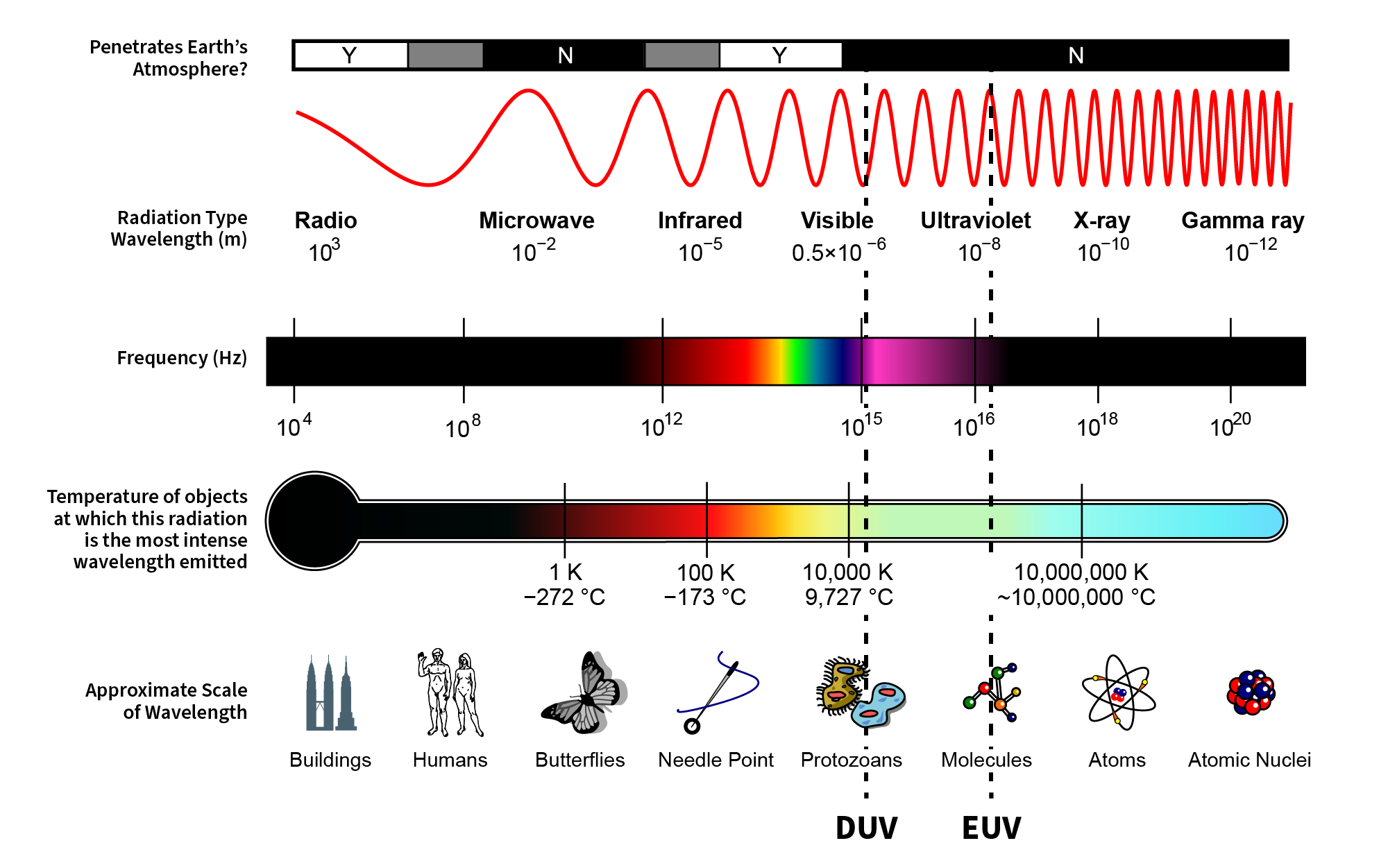

2. The process of manufacturing a microprocessor involves hundreds of complex steps, each of which must be performed with incredible precision. One of the most critical steps is photolithography, which involves using light to etch patterns onto the silicon wafer. The wavelength of light used in this process is a limiting factor in the miniaturization of transistors, with current state-of-the-art processes using extreme ultraviolet (EUV) light with a wavelength of just 13.5 nm. This EUV light is created by a CO2 laser focused on a stream of micrometer sized tin droplets

3. The clean rooms used in semiconductor fabrication are among the most pristine environments on Earth. These rooms are thousands of times cleaner than a typical hospital operating room, with air that is constantly filtered to remove even the tiniest particles. To put this into perspective, a single particle of dust can ruin a microprocessor during production, so the air in a clean room is typically filtered to contain no more than 10 particles larger than 0.1 microns per cubic foot.

4. The heat generated by microprocessors is a major challenge in their design and operation. A modern consumer grade high-performance CPU can generate over 250 watts of heat in a space about the size of a postage stamp. To put this into perspective, this is equivalent to the heat generated by several incandescent light bulb, but concentrated in a much smaller area. Advanced cooling solutions, such as heat spreaders, heat pipes, fans and liquid cooling systems, are necessary to prevent the chip from overheating and failing.

5. Modern microprocessors contain billions of transistors, each of which is a tiny switch that can be turned on or off to represent a binary 1 or 0. The NVIDIA GeForce RTX 4090 GPU contains over 76 billion transistors. If you were to count one transistor per second, it would take you over 2,400 years to count all the transistors in the RTX 4090.

6. The production of microprocessors takes place in highly specialized facilities called semiconductor fabrication plants, or "fabs". These fabs are often considered to be most advanced manufacturing facilities in ever constructed in the world, with some costing over $10 billion to build. The most advanced fabs can produce chips with features as small as 3 nm, and work is underway to develop 2 nm and even 1 nm processes (1 billionth of a meter or about 1/100,000th of a human hair).

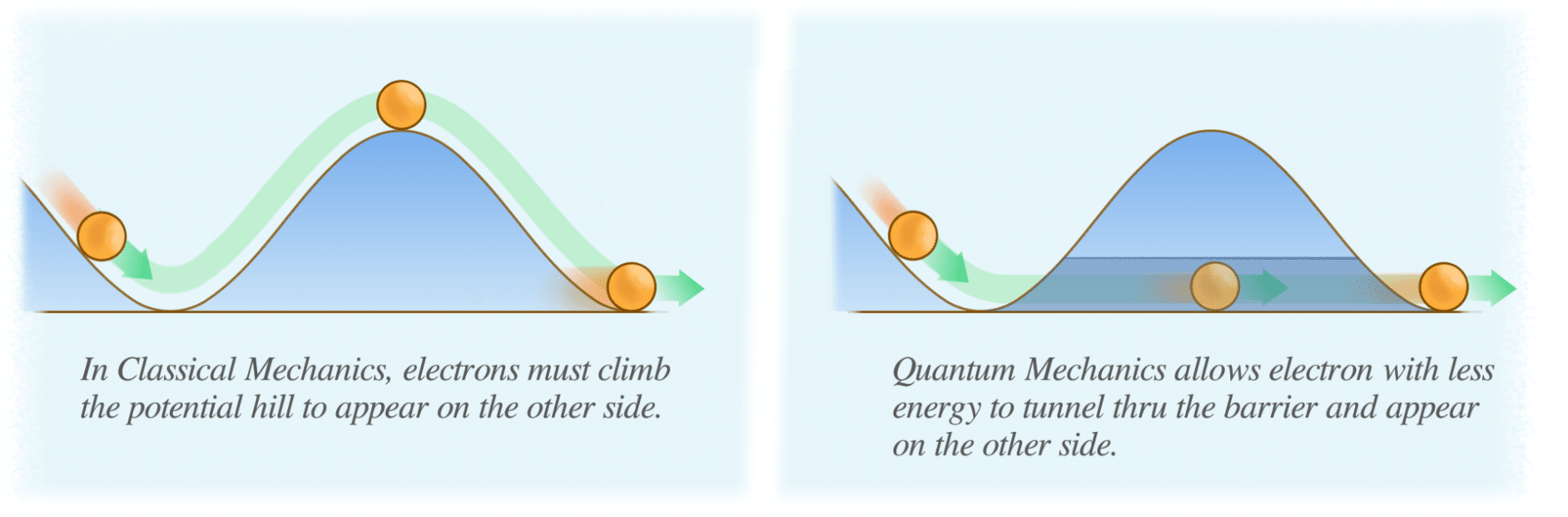

7. One of the key challenges in microprocessor design is dealing with the effects of quantum tunneling. As transistors become smaller, the insulating barriers between different parts of the transistor become thinner, making it easier for electrons to tunnel through them. This can lead to leakage current and reduced performance. To combat this, chip designers are exploring the use of new materials, such as high-k dielectrics and carbon nanotubes, which can provide better insulation at smaller scales.

8. Another challenge in microprocessor design is dealing with the effects of cosmic rays. These high-energy particles, which originate from outside our solar system, can cause bits in the processor's memory to flip, leading to errors and crashes. To mitigate this, chip designers use a variety of techniques, such as error-correcting codes and redundant circuitry, to detect and correct these errors on the fly.

9. The power consumption of microprocessors is a major concern, particularly in mobile and embedded devices where battery life is critical. To reduce power consumption, microchip designers use a variety of techniques, such as clock gating, which turns off unused parts of the chip, and dynamic voltage and frequency scaling, which adjusts the chip's operating voltage and frequency based on the workload. Some modern processors can switch between high-performance and low-power modes thousands of times per second to optimize power consumption.

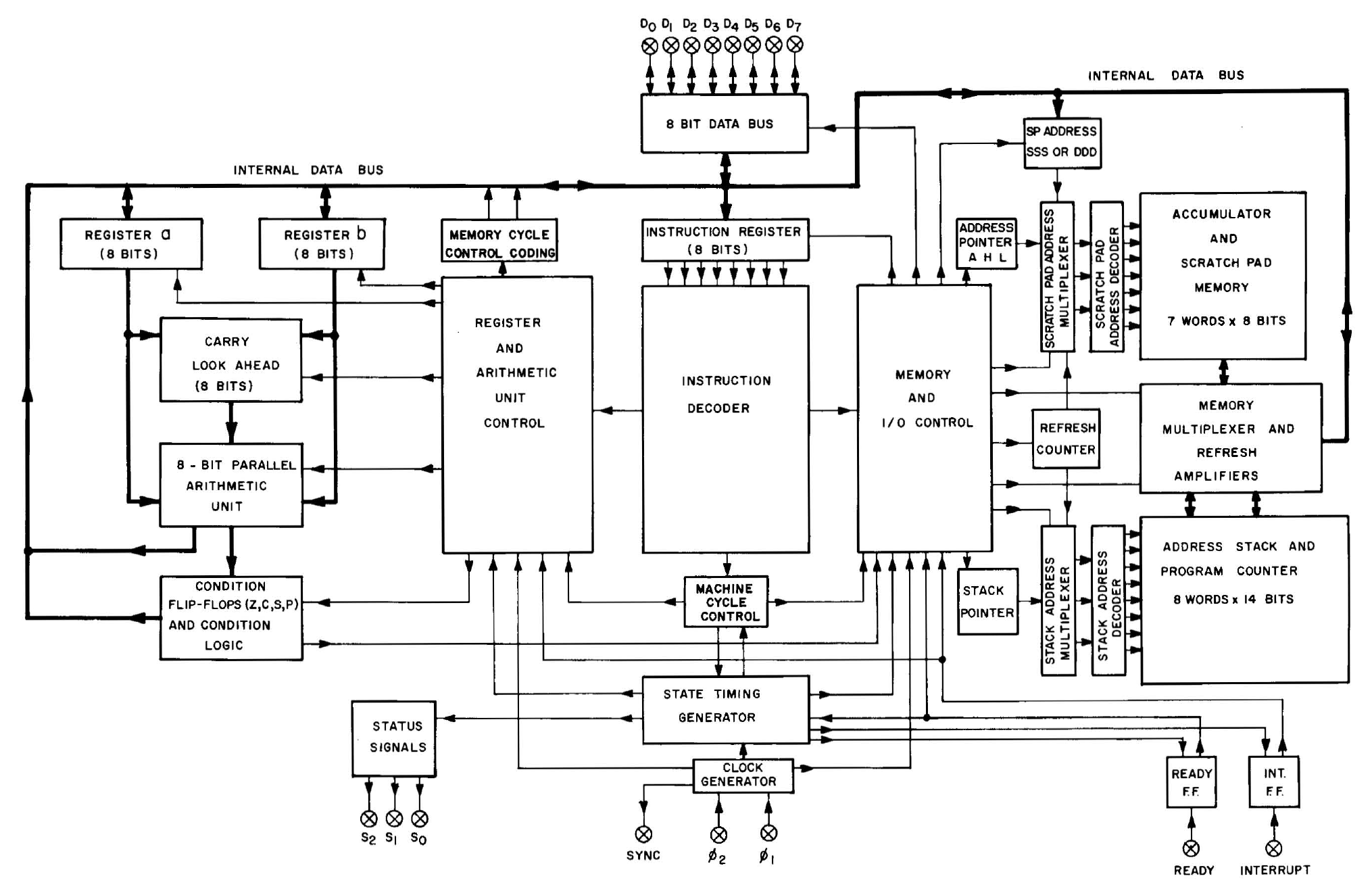

10. The interconnects that carry signals between different parts of a microprocessor are incredibly thin, with some being just a few atoms wide. As chips become more complex, the number of interconnects increases exponentially, creating a "spaghetti-like" structure that is difficult to design and manufacture. To address this, chip designers are exploring the use of new materials, such as copper and low-k dielectrics, which can provide better electrical properties and easier manufacturing at smaller scales.

11. The packaging of a microprocessor is a critical aspect of its design and performance. The package provides electrical connections between the chip and the circuit board, as well as mechanical support and protection. Modern processor packages can contain thousands of pins, each of which must be precisely aligned and connected to the chip. Some high-performance processors use a technique called "flip-chip" packaging, where the chip is flipped upside down and connected directly to the package substrate, allowing for shorter interconnects and better thermal performance.